Magnet Yoke For Smelting Furnace

product presentation

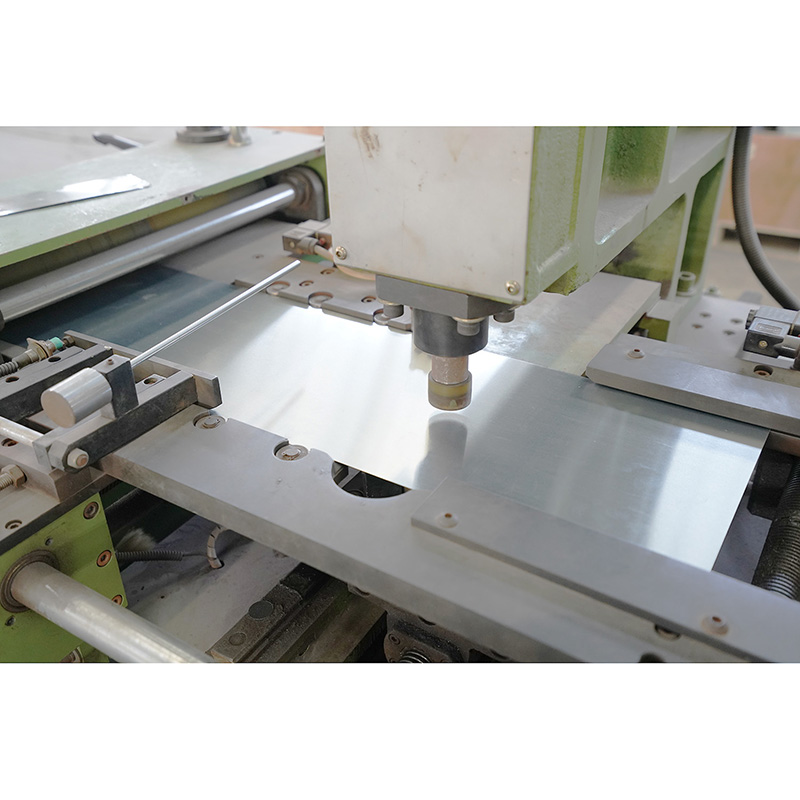

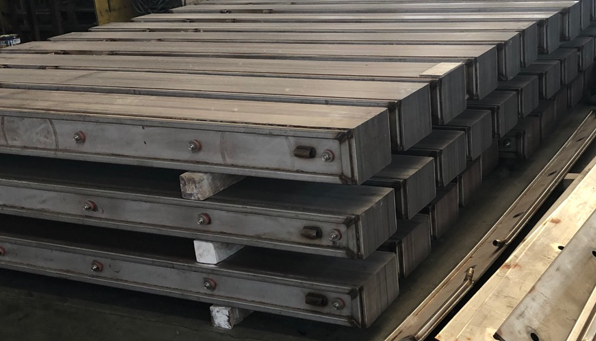

Yoke is made of high permeability cold-rolled silicon steel sheet.Silicon steel sheet thickness is 0.3 mm.The magnetic flux density design under 6000 gauss.

Yoke is clamped and supported by both sides of the 304 stainless steel plate and 304 stainless steel clamp , and rod fixed.Stainless steel plate design effectively increase the sink of oral yoke overheating, the sink tube can withstand a hydraulic pressure of 0.8 MPa, no leak within 15 min.

Yoke assembly after bending is not greater than 4 mm, the center line of the theory and the actual center line deviation is not more than 3 mm.

product advantage

The yoke is a yoke made of laminated silicon steel sheets. It is divided evenly and symmetrically around the induction coil. Its function is to restrict the outward diffusion of the magnetic flux leakage of the induction coil and improve the efficiency of induction heating. In addition, it serves as a magnetic shield to reduce the furnace The heating of metal components such as frames also plays a role in strengthening the sensor.

The furnace body of the intermediate frequency electric furnace has a built-in profiling yoke, and the shielding of the yoke can reduce magnetic flux leakage, prevent the furnace body from heating, and improve efficiency. At the same time, the magnetic yoke plays the role of supporting and fixing the induction coil, so that the furnace body can achieve high strength and low noise. The yoke is a crescent-shaped yoke made of cold-rolled silicon steel sheets and stainless steel splints. The joint surface between the iron core and the coil is a circular arc surface, and the compression part is a surface instead of a line in the past. This structure has the best compression effect. Good, less flux leakage. After the silicon steel sheets are stacked, they are tightened with special splints instead of special through-hole screws. This structure can make full use of the magnetic conduction area of the silicon steel sheets and reduce the possibility of local heating of the intermediate frequency electric furnace body.

A specially designed water-cooled radiator is installed between the yoke and the stainless steel plate clamp. When the intermediate frequency induction furnace is in operation, it can ensure that the upper yoke is in a normal temperature state and prevent its deformation due to high temperature of the yoke, thus strengthening the protection of the yoke. The support of the induction coil improves the overall strength of the furnace.